PLM for Industrial Equipment industries

Let's solve the everyday challenges that hamper your product development processes.

Let's Solve Your Product Development Challenges

Collaborate Globally

Companies are faced with growing organisational complexity, further business acquisitions, and concurrent work communities.

Develop & Deliver Faster

Heightened pressure to reduce time to market, reduce delivery times, while increasing quality.

Leverage Smart Components

Demand for connected sensors everywhere, electrical schematics, machine data historian & analytics.

More Diversity & Emotion

No standard requests, demand for rapid quotes from complex portfolios, from standalone machines to complete plants.

How We Help Industrial Equipment Manufacturers

This solution allows companies to transform from file based to a data driven product structure, moving to a service-based offering that better supports customer engagement. Discover the benefits of Digital Equipment Continuity:

- Enriched Collaboration

- Reduce Time to Market

- Cost-Effective Production

- Higher Product Quality

Sustainably streamline and accelerate your product development, order fulfillment and service activities at any of your locations worldwide. Discover the values of the Single Source for Speed solution:

- All Engineering Data at Your Fingertips

- Monitor On-Time and On-Budget Performance

- Reduce Development Cost and Improve Product Quality

- Optimise Production & Assembly Setup

Synchronise all participating engineering disciplines on a single collaborative platform, and ensure full traceability from needs identification to product validation. Discover the values of Smart and Synchronized:

- Ensure end-to-end traceability

- Master system complexity

- Coordinate multidiscipline design teams

- Reduce number of physical prototypes

- Improve communication between stakeholders

- Simulate machine behaviour early

Enables you to establish product management procedures throughout the product lifecycle, accelerating order fulfillment and meeting customer requirements. Discover the values of Simple Solution Selection:

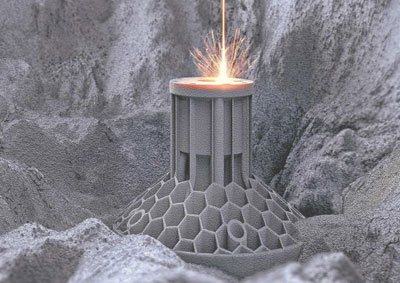

- Design new equipment using modular architecture

- Optimise and get cost efficient production

- Increased product portfolio with part number reduction

- Lower component cost

- Increased volumes

- Improved time to market

- Agile and quick quotation time

Why Choose TECHNIA?

- We combine industry-leading Product Lifecycle Management tools with specialist knowledge, so you can enjoy the journey from product concept to implementation

- We're experienced in developing and supporting the PLM systems within leading Industrial Equipment companies

- We'll help you provide more sophisticated solutions in response to the demands of your customers

- We work closely with leading practitioners in a variety of high-tech industries